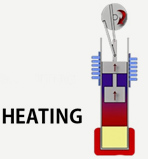

Heating

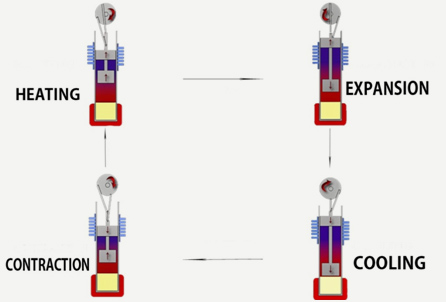

In this stage, the wet steam absorbs the heat from the surface of the hot oil and converts it into Dry steam.

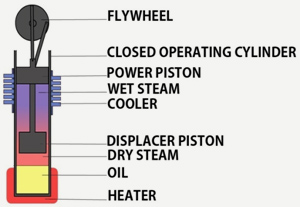

This is a closed type steam engine. Water and Oil has to be poured in to the closed operating cylinder of this Engine. When it is heated, in between the boiling point of water and smoking point of oil, the oil gets converted into heat transfer fluid and the water gets converted into working fluid, which enables the engine to get activated.

In this stage, the dry steam gets expanded. The expanded dry steam pushes the power piston upwards. As the result, flywheel rotates. Simultaneously, by the movement of flywheel, the Displacer piston moves downwards and replaces the expanded dry steam into cooler.

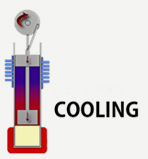

In this stage, the dry steam gets expanded. The expanded dry steam pushes the power piston upwards. As the result, flywheel rotates. Simultaneously, by the movement of flywheel, the Displacer piston moves downwards and replaces the expanded dry steam into cooler. In this stage, Dry steam looses it’s heat in the cooler and gets itself converted into wet steam.

In this stage, Dry steam looses it’s heat in the cooler and gets itself converted into wet steam.

In this stage, the wet steam gets contracted. As a result, the power piston moves downwards and so flywheel rotates. Simultaneously, by the movement of flywheel, the Displacer piston moves upwards and replaces the contracted wet steam on the hot oil surface.

In all these four stages, the same steam recycles itself in the closed operating cylinder and activates the engine.

In this stage, the wet steam gets contracted. As a result, the power piston moves downwards and so flywheel rotates. Simultaneously, by the movement of flywheel, the Displacer piston moves upwards and replaces the contracted wet steam on the hot oil surface.

In all these four stages, the same steam recycles itself in the closed operating cylinder and activates the engine.